The electric vehicle (EV) revolution is undeniable. With millions of EVs now on roads worldwide, and projections indicating exponential growth, a critical question emerges: what happens to the massive batteries that power these vehicles once their automotive life is over? Far from being mere waste, these sophisticated power packs represent a valuable resource. The answer lies in the principles of the circular economy: intelligent utilization and advanced restoration.

This comprehensive article delves into the multifaceted world of used EV batteries, exploring their “second life” applications, the intricate processes involved in their restoration, and the immense environmental and economic benefits of embracing a sustainable battery lifecycle.

The Rise of EVs and the Battery Conundrum

Electric vehicles are hailed as a cornerstone of a sustainable future, offering zero tailpipe emissions and reducing reliance on fossil fuels. At the heart of every EV lies its high-voltage battery pack, typically composed of thousands of individual lithium-ion (Li-ion) cells. These batteries are engineered for performance, longevity, and safety, designed to deliver power for hundreds of thousands of kilometers over 8-10 years.

However, like all batteries, EV packs degrade over time. Their capacity to hold charge diminishes, and their internal resistance increases. While a battery might no longer meet the stringent performance requirements for propelling a car – such as rapid acceleration or extended range – it still retains a significant portion (often 70-80%) of its original capacity. This residual capacity is the key to unlocking their value beyond automotive use, preventing them from prematurely entering the waste stream.

Understanding EV Battery Degradation: More Than Just “Dying”

Battery degradation is a complex process influenced by numerous factors, including:

- Cycling: Each charge and discharge cycle contributes to wear and tear on the battery’s internal chemistry.

- Temperature: Extreme hot or cold temperatures accelerate degradation. Optimal operating temperatures are crucial for longevity.

- Charging Habits: Frequent fast charging, consistently charging to 100%, or regularly discharging to very low levels can stress the battery.

- Calendar Aging: Even unused, batteries naturally degrade over time due to chemical reactions within their cells.

- Manufacturing Imperfections: Slight variations in cell quality can lead to imbalances within the pack, causing weaker cells to degrade faster.

It’s important to differentiate between a battery that has “degraded” for automotive use and one that is truly “dead.” A typical EV battery is considered “end-of-life” for a vehicle when its capacity drops below 70-80% of its original state. At this point, while it may not offer the range or power density required for a car, it is still perfectly viable for less demanding applications.

The “Utilization” Spectrum: Beyond the Road

Before considering restoration, it’s crucial to understand the hierarchy of utilization for used EV batteries. This spectrum maximizes their value and minimizes waste:

1. Second-Life Applications (Repurposing):

This is the most direct and environmentally beneficial form of utilization. Batteries that have served their primary purpose in an EV are repurposed for static energy storage. Their reduced power density is less of a concern, and their remaining capacity can provide many more years of service.

- Grid-Scale Energy Storage Systems (ESS): Perhaps the most significant application. Repurposed EV batteries can store excess renewable energy (solar, wind) and release it during peak demand or when renewable sources are unavailable. This helps stabilize the grid, reduce reliance on fossil fuel “peaker” plants, and integrate more renewables.

- Commercial and Industrial Energy Storage: Businesses can use these batteries to manage their energy consumption, reduce demand charges, and provide backup power during outages.

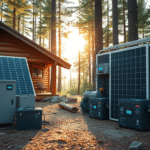

- Residential Energy Storage: Paired with rooftop solar, second-life EV batteries can store solar energy for evening use, increasing energy independence and reducing electricity bills for homeowners.

- Off-Grid Solutions: Providing power for remote communities, disaster relief, or temporary sites where grid connection is impractical or unavailable.

- EV Charging Infrastructure: Integrating second-life batteries into fast-charging stations can buffer the grid impact of high-power charging, especially in areas with limited grid capacity.

2. Recycling (Material Recovery):

When a battery is truly beyond economic restoration or repurposing – perhaps due to severe damage, very low residual capacity, or unrepairable cell failures – it moves to the recycling stage. This process focuses on recovering valuable raw materials.

- Pyrometallurgical Recycling: Involves smelting the batteries at high temperatures to recover metals like cobalt, nickel, and copper. This method is energy-intensive and may not recover lithium efficiently.

- Hydrometallurgical Recycling: Uses chemical solutions to leach out and separate valuable metals from the battery components. This method is generally more efficient for recovering lithium and other high-value materials, and it’s less energy-intensive.

- Direct Recycling: An emerging technology that aims to preserve the cathode structure, allowing for direct reuse of the active material with minimal processing. This is the most efficient but technically challenging method.

The goal of both second-life and recycling is to close the loop on battery materials, contributing to a truly circular economy and reducing the environmental footprint associated with mining new raw materials.

The Art of Restoration: Breathing New Life into EV Batteries

While repurposing used batteries for static storage is a form of utilization, “restoration” takes it a step further. Battery restoration, or remanufacturing, involves a series of sophisticated processes designed to bring a degraded EV battery pack back to a performance level suitable for re-use in an electric vehicle or to significantly extend its life and capacity for second-life applications. This is a complex undertaking that requires specialized knowledge, equipment, and safety protocols.

Here’s a breakdown of the typical steps involved in EV battery restoration:

1. Initial Diagnostics and Assessment:

This is the most critical first step. The battery pack is subjected to a battery of tests to determine its overall health, identify weak points, and assess its remaining capacity and internal resistance.

- Vehicle Diagnostics: Often, initial diagnostics are performed while the battery is still in the vehicle, using the car’s Battery Management System (BMS) data.

- Disassembly and Visual Inspection: Once removed, the pack is safely disassembled (often to the module level) to check for physical damage, corrosion, or signs of overheating.

- Module-Level Testing: Each individual module (a smaller collection of cells) is tested for voltage, internal resistance, and capacity. This helps pinpoint underperforming modules.

- Cell-Level Analysis: For more granular restoration, individual cells within a module may be tested to identify specific weak or dead cells. Advanced diagnostic tools can perform impedance spectroscopy to assess cell health.

- Thermal Imaging: Infrared cameras can detect hot spots, indicating potential internal shorts or high resistance areas.

2. Module and Cell Level Repair/Replacement:

Based on the diagnostic results, specific interventions are planned.

- Weak Cell Identification: The vast majority of pack degradation stems from a small number of underperforming cells that drag down the performance of the entire pack.

- Cell or Module Replacement: If a small number of cells or an entire module is significantly degraded or dead, they can be replaced with healthy, matched cells or modules. Sourcing compatible cells or modules is crucial, often from donor packs or specialized suppliers.

- Welding and Connections: Precision welding (e.g., laser welding) is used to reconnect new cells/modules to the pack’s busbars, ensuring robust electrical connections.

3. Cell Balancing and Reconditioning:

Even healthy cells within a pack can become unbalanced over time due to slight variations in self-discharge rates or charging/discharging patterns.

- Active/Passive Balancing: The BMS constantly tries to balance cells, but during restoration, more aggressive balancing techniques are employed. This involves carefully charging or discharging individual cells or modules to bring them to a uniform state of charge.

- Reconditioning Cycles: Controlled charge and discharge cycles, often at specific rates, can sometimes help “exercise” the battery and recover a small amount of lost capacity or improve internal resistance. This is not a magic bullet but can optimize performance.

4. Battery Management System (BMS) Overhaul and Calibration:

The BMS is the brain of the battery pack, monitoring its health, temperature, voltage, current, and charge state.

- Firmware Updates: The BMS firmware may be updated to optimize performance or address known issues.

- Recalibration: The BMS needs to be recalibrated to accurately reflect the “new” capacity and characteristics of the restored pack. This ensures accurate range estimation and safe operation.

- Fault Code Clearing: Any lingering fault codes from the previous vehicle application are cleared.

5. Safety Checks and Reassembly:

Safety is paramount when working with high-voltage battery packs.

- Insulation and Wiring Integrity: All wiring, insulation, and connection points are thoroughly inspected and repaired if necessary.

- Thermal Management System Check: The cooling system (liquid or air) is inspected and tested to ensure it functions correctly.

- Leak Detection: For liquid-cooled packs, checks for coolant leaks are performed.

- Reassembly: The pack is meticulously reassembled, ensuring all seals, fasteners, and safety mechanisms are correctly in place.

6. Post-Restoration Testing and Certification:

Before a restored pack is deployed, it undergoes rigorous testing to verify its performance and safety.

- Capacity Testing: The most critical test, measuring the actual usable capacity of the restored pack.

- Power Output Testing: Verifying the pack can deliver the required power for acceleration.

- Internal Resistance Measurement: Confirming improved internal resistance.

- Thermal Performance Testing: Ensuring the pack remains within safe temperature limits under various loads.

- Safety Compliance: Adherence to relevant safety standards and regulations.

- Certification: Some companies offer certification for restored packs, providing assurance of quality and performance.

Benefits of EV Battery Restoration and Repurposing

The proactive utilization and restoration of EV batteries offer a cascade of benefits that align perfectly with global sustainability goals:

- Environmental Impact Reduction:

- Reduced Mining: Less demand for virgin raw materials like lithium, cobalt, nickel, and manganese, which are often extracted through environmentally intensive processes.

- Lower Carbon Footprint: Extending the life of existing batteries avoids the significant energy and emissions associated with manufacturing new ones.

- Waste Diversion: Prevents millions of tons of battery waste from accumulating in landfills.

- Economic Advantages:

- Cost-Effective Energy Storage: Second-life batteries offer a significantly cheaper alternative to new batteries for static storage applications, making renewable energy storage more accessible.

- New Business Models: Creates entirely new industries and job opportunities in battery diagnostics, repair, remanufacturing, and system integration.

- Reduced EV Ownership Costs: Restored battery packs can provide a more affordable replacement option for EV owners, extending the useful life of their vehicles.

- Enhanced Grid Stability: Cost-effective energy storage helps utilities manage peak loads, integrate renewables, and avoid expensive infrastructure upgrades.

- Resource Conservation and Security:

- Maximizing Value: Extracts maximum utility from high-value, energy-intensive manufactured products.

- Supply Chain Resilience: Reduces reliance on volatile global supply chains for critical battery materials.

- Energy Independence: Strengthens energy security by providing diverse and sustainable energy storage solutions.

Challenges and Considerations

Despite the clear advantages, the path to widespread EV battery utilization and restoration faces several hurdles:

- Technical Complexity: Lithium-ion batteries are complex and require specialized expertise and equipment for safe handling, diagnosis, and repair. Thermal runaway (fire) risk is a serious concern if not handled properly.

- Safety Protocols: High voltages and potential for thermal events necessitate strict safety training, protocols, and facilities.

- Lack of Standardization: There’s currently no universal standard for testing, grading, or certifying used EV batteries, making it challenging to assess their true value and performance consistently.

- Data Access: Manufacturers often hold proprietary data on their battery packs and BMS, which can hinder independent restoration efforts.

- Logistics and Scale: Managing the collection, transportation, and processing of millions of battery packs will require robust logistical networks.

- Economic Viability: The cost-effectiveness of restoration versus new battery manufacturing depends on the level of degradation, the cost of labor, and the price of new materials.

The Future of EV Battery Circularity

The future of EV battery utilization and restoration is bright, driven by increasing environmental awareness, economic incentives, and technological advancements. Research and development are continuously improving diagnostic tools, repair techniques, and recycling processes. Policy makers are also beginning to implement regulations and incentives to encourage circularity in the battery industry.

As the EV market matures, the infrastructure for battery second life and restoration will expand, becoming an integral part of the automotive ecosystem. From providing affordable energy storage for homes and grids to extending the life of electric vehicles themselves, used EV batteries are transforming from potential waste into a powerful resource, fueling the transition to a truly sustainable and circular economy.

By embracing innovative approaches to battery utilization and restoration, we can ensure that the electric vehicle revolution not only cleans our air but also builds a more resource-efficient and sustainable future.